stern tube seal leak test|temperature of stern tube seal : distributor A testing setup was developed, allowing an insight into the actual operation conditions of stern tube seals. The rig made it possible to accurately . Conecte-se - Elephantbet | Casa de Apostas em Angola

{plog:ftitle_list}

Resultado da Prestamos serviços de Logística e Transporte para Eventos, Translados, Receptivo, Passeios, Viagens e Excursões, Aluguel de Vans, com sede na cidade de Florianópolis e .

A testing setup was developed, allowing an insight into the actual operation conditions of stern tube seals. The rig made it possible to accurately . Prime amongst these dry air examinations and repair scenarios, a stern tube integrity test is always conducted in a drydock, where the test fittings, including the air bladder and gauges, can be installed while a second engineer .

Pre-launching: L/O pipe leak test: stand for 8hours. In water survey ( IWS ): for bearing wear. F WD seal alignment at Post launching: 3. Summary: Above is some notes for .Stern tube seals are a key component of the propulsion system of a ship. The purpose of these sealing rings is to ensure a reliable sealing condition, preventing the spillage of lubricant to the .

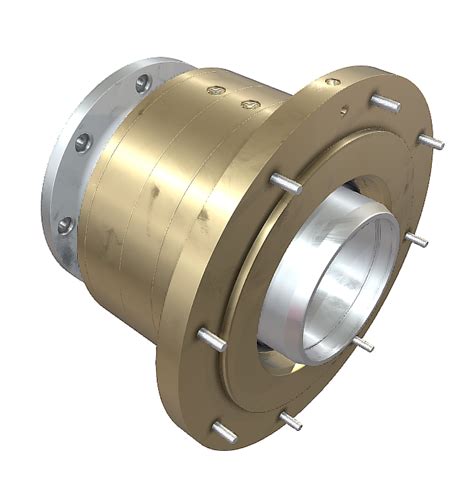

This paper studies and analyzes the leakage of a ship’s sterntube sealing device, analyzes the basic principle and failure mechanism of the ship's sterntube sealing device, and explains the .The basic function is to prevent oil leakage from and seawater penetration into the stern tube. The most popular oil lubricated seal is a lip type seal and an example is shown in Fig. 1.

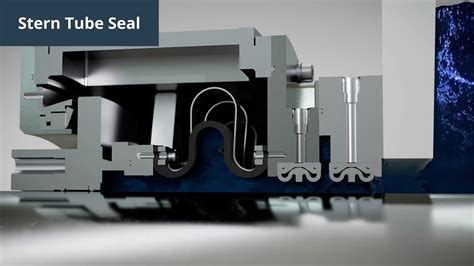

A dynamic setup replicating the operating conditions of a stern tube seal is presented together with a novel arrangement for monitoring the flow rate across the seal. Seal Integrity Testing: Perform seal integrity tests to ensure that the air seals effectively prevent water ingress. This may involve shutting down the system and conducting a thorough examination. Troubleshooting Stern Tube .

We speak of leakage when there is an excessive amount of water ingress to the stern tube, or oil leakage to the engine room or the marine environment of a vessel. A leakage is defined as any loss of oil beyond this .

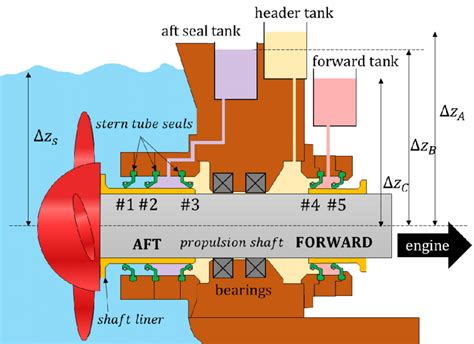

shaft typically supported by oil lubricated white metal bearings with the oil contained in the stern tube by shaft seals. This “sealed stern tube system” is filled with mineral oil and sealed typically with a forward and aft lip type seal at each end as shown in Figure 1. Typical stern tubes contain 1500L (396 US gal) of mineral oil. The Disposition of the oil tanks feeding the chambers between the stern tube seals. Source: Wärtsilä. Although various seal dispositions exist, the arrangement shown in Figure 1 and Figure 2 is the most common one. Seal #1 faces the water side and works as a dirt excluder. This outermost seal is rapidly worn out, hence seal #2 also faces the water.Lip Seals. In the case of a smaller leak below 15l-20l per day, then the STERN TUBE SL is the best product to use. If you have a larger leak than 15l-100l, then our STERN TUBE SLL is the relevant choice. It has the same properties as STERN TUBE SL, but contains larger and more complex particles.Leakages in stern tube seals occur when they are least expected. ABCON provides simple and efficient solutions addressing these leakages. By adding one of our STERN TUBE SL (Stop Leak) series of additives to the existing system oil, a Teflon barrier is created on the damaged seal which reduces the leakage significantly or stops it altogether.

Following on from having the gearbox repaired I have had an issue with a leak from the stern tube. Unlike the majority of narrowboats which seals around the .

killing them softly shotgun test

temperature of stern tube seal

tion across the seal are measured under various shaft velocities and pressure differences. The existing theory for rotary lip seals is reviewed for the stern tube seal application. From the results it is deduced that the stern tube seals tested operate within the elastohydrodynamic regime with film thicknesses in the sub-micrometer range. Keywordstion across the seal are measured under various shaft velocities and pressure differences. The existing theory for rotary lip seals is reviewed for the stern tube seal application. From the results it is deduced that the stern tube seals tested operate within the elastohydrodynamic regime with film thicknesses in the sub-micrometer range. Keywords

AtZ were asked to carry out a stern tube inspection. The vessel had reported leakage from one of their two Wartsila MD stern tube shaft seals of 16 litres per day or more but was unsure if there was likely failure that would require stopping the shaft, or whether the issue could be resolved in service. ATZ has a great deal of propulsion, seal and bearing experience including the design .Preventing Water Ingress: The primary purpose of stern shaft seals is to prevent water from entering the vessel through the stern tube where the propulsion shaft passes through. Proper installation and fitting of these seals are crucial to maintaining a watertight barrier and preventing water ingress into the vessel's hull. Good day, Engineers In my ship after last discharge, sea water is leaking into stern tube sealing oil tank. Evry 2 hours need to drain sea water from stern tube sealing oil tank. . Is it aft seal or forward seal, How can i understan? Ask yourself: Which one of those separates shaft oil from sea water? Howard1 May 11, 2019, 8:28pm 5. I agree. .

Afloat Stern Seal Repair Port of Rotterdam ROG Ship Repair and AEGIR-Marine were contracted to replace a leaking stern tube seal, with the vessel afloat. When the vessels was trimmed by the bow, a staging was welded and the rope guard was removed. . After the seals were renewed by means of bonding, a leak test was successfully executed. The .

Ineffective marine seals can be prone to water ingress that can be damaging to the system as it causes less lubricity and more corrosion. Add an oil leakage into the mix and you could face considerable maintenance costs and unplanned downtime. For over 70 years, Simplex sterntube seals have offered the marine industry a solution. .propellers run in journal bearings mounted inside the stern tube filled with oil. The radial movements of the propeller shaft in the bearing are larger than those of other industrial shafts and may be intensified by the force of waves or vibrations. Radial shaft seals or mechanical seals prevent the oil from leaking into the sea and also keep .Oil Filling and Oil Pressure Test Procedures for oil filling to stern tube and oil pressure test for Air Seal is described in P. 6. Confirm actual valve operation for oil filling, circulation, draining & etc. in ship’s piping diagram available in finished plan. 3. Operation of .

Simplex Sterntube seals. Prevent ingress of water and avoid lubricating oil leakage. Water ingress can be damaging to the system as it causes less lubricity and more corrosion. Add an oil leakage into the mix and you could face . Seafarers - Technical Guide for Marine Engineers-----Nitrogen Generator : http://n.

Thank you very much for buying our EVK stern tube seal this time. Please read this instruction manual carefully before use, and then use it correctly. . If a large amount of water (over 100 – 200 L/day) leaks continuously, check the seal ring and replace it if necessary. (1)Work the inflatable ring according to item 2. (2)Remove the mating .

The industry also noted stern tube oil leaks could be a substantial source of oil pollution. - 3 - MEPC 58/INF.22 I:\MEPC\INF-22.doc . 10 In 2007, a major stern tube seal repairer, Simplex Americas LLC, repaired a large tanker stern tube seal that was damaged due to fishing line. This was the twenty-first stern tube sealTable of Contents Description of DryMax® Shaft Seal System The DryMax® Stern Tube Seal System was designed, built, and test-ed by Duramax Marine® in the USA . The seal is a water-lubricated axial shaft seal system constructed of the highest quality materials which are engineered to give you long service life . The DryMax®

stern tube seals explained

Stern tube seals are one of the largest types of lip seals. These components are widely used in static, rotary, and reciprocating sealing applications. Rotary lip seals are designed, so that a sharp tip at the edge of the lip acts as a physical barrier to prevent leakage through the seals. Stern tube seals are I have the standard Volvo Penta Stern Gland seal on my Beneteau Oceanis 37, with a 25mm shaft and 43mm stern tube. The boat is a 2009 model, and the Yanmar 3YM30 engine has around 800 hours. The original seal did not leak, but was getting rather old, so I replaced it two years ago. Simplex seals have been setting standards in the shipping industry for over 70 years and remain at the cutting edge of sterntube seal technology. This video .

In summary, a reliable test starts with a reliable seal. Confidence in your leak test begins by reducing or eliminating all the external factors that can undermine accuracy and repeatability. Quality engineers and operators must understand and compensate for variations in the air supply, the thermal effects of compressed air, the impact of .For face seals we have our ABCON MARINE-STERN TUBE CSL which is designed to stop leaks and water ingress in small and large Cedervall type seals (below 100 liters/day). Properties of STERN TUBE SL. The unique properties of our Stop Leak products are their abilities to produce a teflon barrier on the leaking area as well as reducing wear and tear.Standard test scope for Stern tube Testing. Test Parameter Method; Kinematic Viscosity @40°C : ASTM D 445: Water: ASTM D 6304: Acid Number: ASTM D 664: Soot / Insolubles (ASTM D789913;ASTM D89314; ASTM E241210) . Usage of mineral lube compatible seals with EALs can lead into catastrophic failures. Water content in the in-service EAL shall be .

lachman test soft endpoint

WEB9 de fev. de 2022 · O K-drama "Snowdrop", uma produção do Drama House Studio, dos estúdios da "JTBC", chegou oficialmente ao país nesta quarta-feira, dia 9, por meio da plataforma de streaming Star+. Inicialmente .

stern tube seal leak test|temperature of stern tube seal